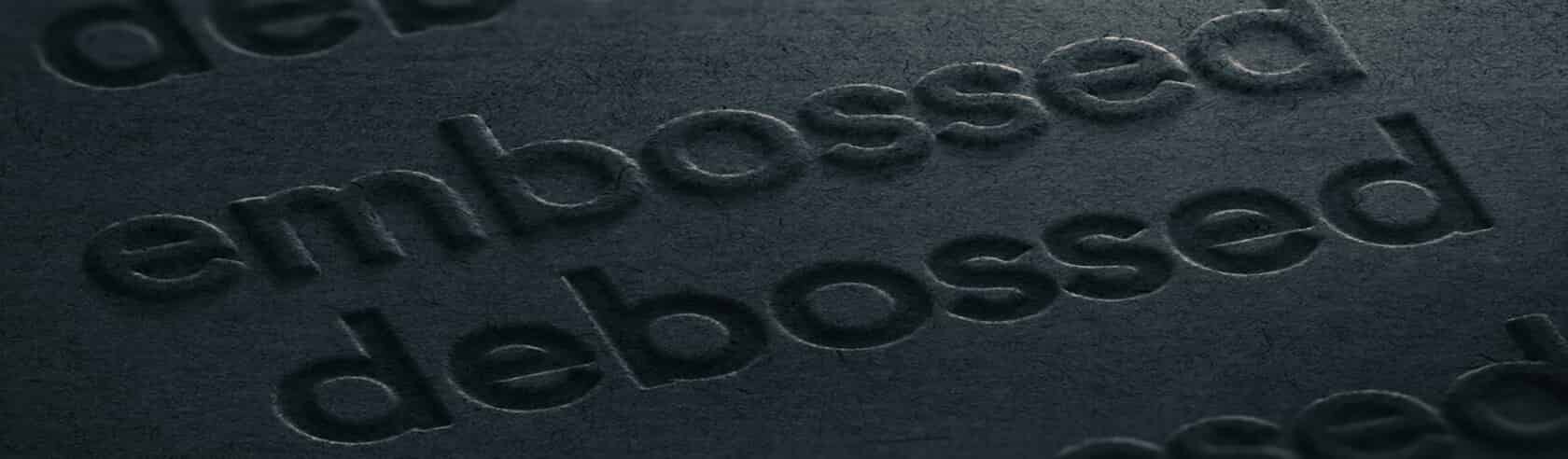

There is no such thing as a brand-new term for embossing and debossing in the packaging industry. Boxing and packing use both of these techniques extensively. In other words, these are the add-ons and embellishments we use to beautify our packaging. Here are two of the most famous methods that we can differentiate and explain:

Embossed vs. Debossed

Paper, textiles, leather, and plastic can be embossed or debossed in many ways. It is the process itself that differentiates these two:

-

Applying pressure to your product's surface with heated dies results in an embossed image or lettering.

-

A debossed product has the top of the material removed to reveal a debossed print or lettering instead.

These definitions still need to be completed, however. Understanding their roles and basic techniques is essential to a comprehensive overview of these two. All that is needed is information to understand these add-ons' role in custom packaging.

How Embossing Works

Embossing involves transferring an image or text from a thin piece of metal onto paper or cardstock by applying high pressure. Embossing is engraving an idea into a material using a mold (sometimes called stamping). Then, use a cotton ball to remove any excess liquid. In addition to greeting cards and book covers, CD sleeves can be created using this process.

How Debossing Works

On the other hand, a debossed surface has an impression that appears recessed rather than raised since it is suspended (or depressed). As with embossing, the reverse process is almost identical.

Both techniques are essential for the highest quality packaging and printing results. Because most producers copycat one another, buyers see similar items side by side, which makes your package stand out. A variety of lamination options are available to enhance it further.

Branding information can also be distinguished from your competitors by embossing and debossing.

What is the Difference Between Embossing and Debossing?

What are the similarities between them? Many readers and manufacturers may have this question in mind. Newcomers to that field are especially at risk. Embossed and debossed prints alter a print's surface area, as discussed above. Similarity exists in the mechanisms and procedures but not in the results. Light pressure is used to apply ink to the substrate when embossing an object. When ink sinks into the paper pores, it leaves an impression that can be felt.

-

Debossing

In contrast, debossing occurs when the top layer is pushed up by pressure from underneath. A linear, even application of ink without texture or tactile properties results in an indented impression.

-

Embossing

Cards with embossed images, high-quality stationery, and greeting cards are some of the items that commonly have embossed images.

Debossing and Embossing Techniques

A debossing machine or an embossing machine makes an impression on paper using either embossing or hot stamping.

The paper is raised or recessed on the surface of these machines to create patterns. Consumers will find it more appealing visually and tactilely that way. This machine can emboss and deboss using three different techniques, each of which affects the look of the paper differently:

-

The offset printing processes

-

A letterpress printing process

-

A thermography printing process

Paper embossed with embossing ink is usually white or clear. Until it reaches the front of your card, extending the entire sheet.

Packaging and other industry examples

There are two ways of embossing, either on paper or metal. When sandblasting a design onto the wood, embossing paper creates an uneven relief reflecting light in various colors.

As opposed to embossing, debossing removes ink or metal from the surface. Using this technique, the light will be less reflected when it hits the sunken relief. The product is, therefore, incompatible with metal and other rough surfaces.

Embossing and Debossing are Not the Same Thing

In addition, there often needs to be more clarity between impression and embossing or debossing. What is an impressive technique? Here is what makes it different from

How about raising or lowering a design on paper, cardstock, or fabric? Impressions can be used to accomplish this. We emboss a structure by applying pressure or heat to it. The process is often done without heat, however. Paper, cardstock, plastic, etc., are more suitable packaging materials.

This tool has two parts - the handle, which is squeezed tightly to apply pressure, and the roller, which has an interchangeable cover.

Conclusions

Making your materials more three-dimensional can be achieved by embossing or debossing. Embossed or debossed effects can be achieved with various tools but typically involve applying pressure, such as heat or water, to the surface.

To avoid damaging the material you're working on, remember to use all types of design tools, such as embossing and debossing. If you use it for anything, it will benefit your output.